-

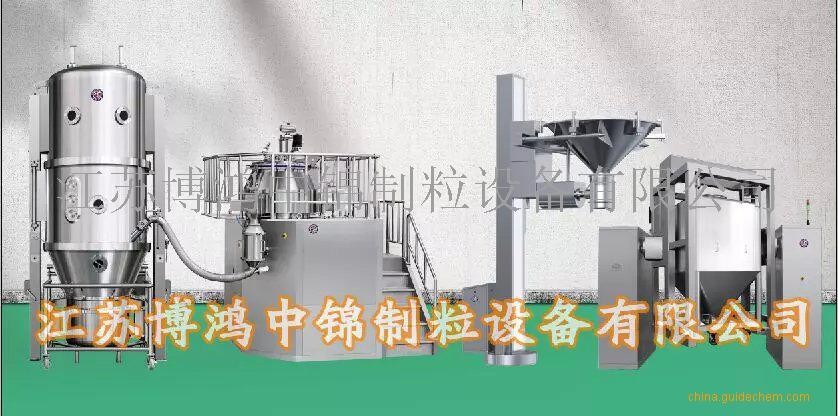

你好,欢迎来到江苏博鸿中锦制粒设备有限公司官网!

|

| 外型尺寸 | 3*5*8 |

| 品牌 | 高速离心喷雾干燥机 MSD series high speed centrifugal spray dryer |

| 货号 | MSD-100 |

| 用途 | 江苏博鸿提供的喷雾干燥机,压力喷雾干燥塔,离心式喷雾干燥机,卧式压力喷雾干燥机,流化床喷雾干燥制粒机,上排风多级流化床喷雾造粒干燥机,中药浸膏喷雾干燥机,符合医药GMP/FDA要求。 |

| 型号 | MSD-100 |

| 制造商 | 分散剂专用压力喷雾干燥塔 染料高速离心喷雾干燥机 低温喷雾造粒烘干机 |

| 是否进口 |

MSD series high speed centrifugal spray dryer

喷雾干燥机|上排风流化床喷雾干燥制粒机|卧式压力喷雾造粒干燥机

Spray dryer | Upper exhaust fluidized bed spray drying granulator |

Horizontal pressure spray granulator dryer

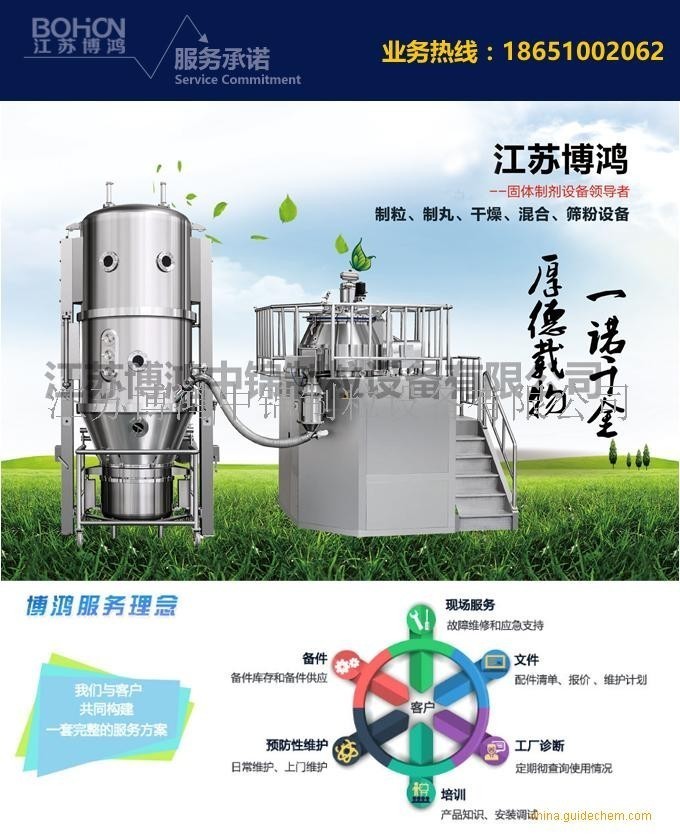

江苏博鸿提供的喷雾干燥机,压力喷雾干燥塔,离心式喷雾干燥机,卧式压力喷雾干燥机,流化床喷雾干燥制粒机,上排风多级流化床喷雾造粒干燥机,中药浸膏喷雾干燥机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥设备性能稳定,模块化设计,为您提供先进的喷雾干燥整体解决方案和实验喷雾干燥工艺实验样机。江苏博鸿是高品质喷雾干燥设备生产厂家,已提供超数百套高品质喷雾干燥设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong spray dryer, pressure spray drying tower, centrifugal spray dryer, horizontal pressure spray dryer, fluidized bed spray granulating machine, upper exhaust multi-stage fluidized bed spray granulating dryer, Chinese medicine extract spray dryer, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying equipment stable performance, modular design, to provide you with advanced spray drying solutions and experimental spray drying process experimental prototype. Jiangsu bohong is a high quality spray drying equipment manufacturers, has provided more than hundreds of high quality spray drying equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

一、MSD系列高速离心喷雾干燥机--设备概述

MSD series high-speed centrifugal spray dryer -- equipment overview

高速离心喷雾干燥机主要适用于高校、研究所和食品医药化工企业实验室生产微量颗粒粉末,对所有溶液如乳浊液、悬浮液具有广谱适用性,适用于对热敏感性物的干燥如生物制品、生物农药、酶制剂等,因所喷出的物料只是在喷成雾状大小颗粒时才受到高温,故只是瞬间受热,能保持这些活性材料在干燥后仍维持其活性成份不受破坏。

High-speed centrifugal spray drying machine is mainly suitable for colleges and universities, research institutes and the food and medicine and chemical industry enterprise laboratory trace particles of powder production, such as emulsion, suspending liquid has a broad spectrum of all solution applicability, suitable for drying thermal sensitivity material such as biological products, biological pesticide, enzymes, because of overflowing material only when sprayed into mist particle size under high temperature, it is just instant heating, can maintain the active material in dry hind still maintain its active ingredients are not destroyed.

二、MSD系列高速离心喷雾干燥机--工作原理

MSD series high speed centrifugal spray dryer - working principle

空气经过滤和加热,进入干燥器顶部空气分配器,热空气呈螺旋状均匀地进入干燥室。料液经塔体顶部的高速离心雾化器,旋转喷雾成极细微的雾状液珠,与热空气并流接触在极短的时间内可干燥为成品。

The air is filtered and heated and enters the air distributor at the top of the dryer. The feed liquid passes through the high speed centrifugal atomizer on the top of the tower body, and turns the spray into extremely fine mist droplets, which can be dried into finished products in a very short time after contacting with the hot air.

喷雾干燥机热气流与雾滴的接触:有足够量的热气流进入喷雾干燥室时,必须考虑热气流的方向及角度,无论是并流、逆流还是混流,确保与雾滴的充分接触,才能进行充分的热交换。

Contact between hot air flow and fog droplets in spray dryer: when enough hot air flow enters the spray drying chamber, the direction and Angle of hot air flow must be considered, whether it is parallel flow, reverse flow or mixed flow, to ensure the full contact with fog droplets, in order to carry out full heat exchange.

喷雾干燥机成品连续地由干燥塔底部和旋风分离器中输出,废气由风机排空。整套喷雾系统易清洁、无死角,符合GMP要求。

The finished product of the spray dryer is continuously output from the bottom of the drying tower and the cyclone separator. The whole spray system is easy to clean, no dead corner, in line with GMP requirements.

三、MSD系列高速离心喷雾干燥机--产品特点

MSD series high speed centrifugal spray dryer -- product features

《1》高速离心喷雾干燥机干燥速度快,料液经雾化后表面积大大增加,在热风气流中,瞬间就可蒸发95%-98%的水份,完成干燥时间仅需数秒钟,特别适用于热敏性物料的干燥。

High speed centrifugal spray dryer drying speed, the surface area of the material after atomization greatly increased, in the hot air flow, can instantly evaporate 95-98% of the water, drying time only a few seconds, especially suitable for the drying of heat-sensitive materials.

《2》高速离心喷雾干燥机产品具有良好的均匀度、流动性和溶解性,产品纯度高,质量好。对于含湿量40—60%(特殊物料可达90%)的液体能一次干燥成粉粒产品,干燥后不需粉碎和筛选,减少生产工序,提高产品纯度。对产品粒径、松密度、水份,在一定范围内可通过改变操作条件进行调整,控制和管理都很方便。

High speed centrifugal spray dryer has good uniformity, fluidity and solubility, high purity and good quality. For the liquid with moisture content of 40-60% (up to 90% for special materials), it can be dried into powder products at one time. After drying, there is no need to crush and screen, which can reduce the production process and improve the product purity. The product size, loose density and moisture can be adjusted by changing the operating conditions within a certain range, which is very convenient for control and management.

《3》喷雾干燥机采用彩色大触摸屏操作,全自动控制和手动控制相结合,满足用户调节各项参数的要求,在干燥温度控制的设计上采用实时调控PID恒温控制技术。

The spray dryer is operated with a large color touch screen, with the combination of automatic control and manual control to meet the user's requirements for adjusting various parameters. In the design of drying temperature control, the machine adopts real-time PID thermostatic control technology.

《4》生产过程简化,操作控制方便。一键式开机,全自动控制。设定喷雾工艺参数后,温度到达预定温度,泵自行启动,触摸屏上显示运行动画,运行流程清晰显示;关机时只需按停止键,机器自动安全关机。

The production process is simplified and the operation and control are convenient. One-button startup, fully automatic control. After setting the spray process parameters, the temperature reaches the predetermined temperature, the pump starts up by itself, the running animation is displayed on the touch screen, and the running process is clearly displayed. When the machine is shut down, just press the stop button and the machine will shut down automatically and safely.

一、ZLPG系列中药浸膏喷雾干燥机--设备概述

ZLPG series Chinese medicine extract spray dryer -- equipment overview

中药浸膏是由植物根茎叶提取而成,特别是醇提工艺,它含糖份较高,在高温下易软化熔融,普通的离心喷雾已无法满足干燥,针对这种情况江苏博鸿公司组织了精干的技术力量,设计制造喷雾干燥机的成功经验,收集了国内外同行业同类型产品的优点,经过精密、反复的工艺计算和无数次的实验,开发出了中药浸膏专用喷雾干燥机组,并推广到了一些知名药厂使用。

Chinese traditional medicine extract is made from a plant root leaf extract, alcohol extraction process, in particular, it contains high sugar, softening melting at high temperature, ordinary centrifugal spray have been unable to meet the dry, aimed at the situation of jiangsu bo hong company organized capable technical force, the successful experience of design and manufacture of spray dryer, collecting the advantages of the similar products in the same industry at home and abroad, through precision, repeated process calculation and countless experiments, developed a Chinese medicine extract spray dryer, and promote to some well-known pharmaceutical factories.

二、ZLPG系列中药浸膏喷雾干燥机--工作原理

ZLPG series Chinese medicine extract spray dryer - working principle

中药浸膏高速离心喷雾装置是离心式喷雾干燥技术在特定物料干燥中的应用,也是利用高速离心式雾化器使物料分散成雾状,与热空所充分接触,完成瞬间干燥,形成粉状成品的干燥装置。

The high speed centrifugal spray device for traditional Chinese medicine extract is the application of centrifugal spray drying technology in the drying of specific materials. It is also a drying device that USES the high speed centrifugal atomizer to disperse the materials into a mist and make full contact with the hot air to complete instant drying and form a powdery finished product.

三、ZLPG系列中药浸膏喷雾干燥机--设备优势

ZLPG series traditional Chinese medicine extract spray dryer -- equipment advantages

中药浸膏专用喷雾干燥机是专门用来解决,中药浸膏和植物提取液的喷雾干燥机,它解决了物料在原LPG高速喷雾干燥机在中药浸膏干燥中出现的以下情况:

The special spray dryer for traditional Chinese medicine extract is a spray dryer specially used to solve the problems of traditional Chinese medicine extract and plant extract. It solves the following problems in the drying of traditional Chinese medicine extract in the original LPG high-speed spray dryer:

1、物料粘壁,收粉率低;

The material sticks to the wall, the powder yield is low;

2、物料在壁上停留时间长,产生物料的焦化变质现象;

The material stays on the wall for a long time, resulting in coking deterioration of the material;

3、难以清洗,不符合GMP要求;

Difficult to clean, not in line with GMP requirements;

4、产量低:LPG-150型喷雾干燥机,其产量只能处理50-60kg/h料液。

Low yield: lpg-150 spray dryer can only handle 50-60kg/h liquid.

鉴于以上状况,江苏博鸿根据中药浸膏的物料性质与工艺要求设计中药浸膏干燥机难题,干燥后的物料颜色好、不变质、大大地提高了工厂的经济效益,中药浸膏与MSD系列高速离心喷雾干燥机相比有以下特点:

In view of the above situation, jiangsu bohong according to the material properties and process requirements of traditional Chinese medicine extract design traditional Chinese medicine extract dryer problem, after drying the material color is good, do not deteriorate, greatly improve the economic benefits of the factory, traditional Chinese medicine extract and MSD series high-speed centrifugal spray dryer has the following characteristics:

1、采用了空气处理系统采用初中高三级空气过滤,使进风达到30万级要求;

The air treatment system adopts high and middle level air filtration, which makes the air inlet reach the level of 300,000.

2、采用了具有冷风夹套,冷壁装置,使内壁温度达到80℃,物料在壁上停留也不焦化;

With cold air jacket and cold wall device, the inner wall temperature reaches 80℃, and the material stays on the wall without coking;

3、塔径塔高做了相应的调整,既保证物料干燥之前接触不到塔壁,又保证物料在热风中的停留时间;塔壁设有夹套冷风冷却装置,确保物料吸附在塔壁上因局部温度过高而产生软化、熔融甚至焦化现象;

The diameter and height of the tower have been adjusted accordingly to ensure that the materials can not reach the wall of the tower before drying and the residence time of the materials in the hot air. The tower wall is provided with jacket cold air cooling device to ensure that materials adsorbed on the tower wall will soften, melt and even coking due to excessive local temperature;

4、主机内所有与物料接触处采用平面或圆弧过渡,接触面都进行打磨、抛光工序处理(精抛至10以上),避免砂眼、死角。

All contact points with materials in the main machine shall adopt a plane or arc transition, and the contact surface shall be polished and polished (fine casting to 10 or more) to avoid sand holes and dead corners.

5、杜绝积料堵料;整个机组与物料接触处材质采用不锈钢,保证物料不受污染;与物料接触的传动件都采用良好的密封,可防水防油;出料处用密封蝶阀操作,防止漏风;

Put an end to the accumulation of material blocking; The contact between the whole unit and materials is made of stainless steel to ensure the materials are not polluted. The transmission parts in contact with materials are well sealed, waterproof and oil-proof; The outlet shall be operated by sealed butterfly valve to prevent air leakage;

6、锥角增大,锥体上安装空气震击器,用压缩空气脉冲式地震击筒体,把吸附在筒体上的粉料顺畅地击落下来;

With the increase of the cone Angle, an air jar is installed on the cone, and the compressed air pulse type seismic hammer is used to knock down the powder adsorbed on the cylinder smoothly.

7、引风出料管段都采用活连接,可随时拆装、清洗、消毒、灭菌处理等等;适用于多品种生产要求。

The air outlet pipe is connected with live connection, which can be disassembled, cleaned, disinfected and sterilized at any time. Suitable for multi - variety production requirements.

8、除尘采用了湿式除尘,使粉尘无外出,符合环保要求;

Dedusting adopts wet dedusting to keep the dust out and meet the requirements of environmental protection.

9、采用了PLC控制,程控系统屏幕显示;

PLC control, program control system screen display;

10、配备在线清洗装置;塔体、管路配有快开清洗孔及排污孔;

Equipped with on-line cleaning device; The tower body and pipelines are equipped with quick opening cleaning holes and blowdown holes;

11、配备气扫装置、采用干空气密封闭输送;

Equipped with air scavenging device and sealed with dry air;

12、采用PLC程序控制系统回路;触摸屏动画显示工艺流程,具有可操作性,变量操作参数实现模糊技术自动跟踪调节;用变频器稳定安全地调节雾化器;进、出风温度、塔内压力数显,可设定数字。

PLC program control system loop; The touch screen animation displays the technological process, which is operable. The variable operating parameters can be automatically tracked and adjusted by fuzzy technology. Adjust the atomizer stably and safely with frequency converter; Inlet and outlet air temperature, tower pressure digital display, can set the number.

一、WZ系列卧式喷雾干燥机--设备概述

WZ series horizontal spray dryer -- equipment overview

卧式喷雾干燥机是干燥领域发展快、应用广的一种形式,适用于溶液、乳浊液和可泵送的的悬浮液等液体原料生成粉状、颗粒状或块状固体产品,经卧式喷雾干燥机喷雾干燥成为干燥粉末状、细中颗粒的制品。

Horizontal spray dryer is a form of rapid development and wide application in the field of drying, suitable for liquid raw materials such as solution, emulsion and pumpable suspension to produce powder, particle or block solid products, by horizontal spray dryer spray drying into dry powder, fine medium particle products.

卧式喷雾干燥机其工作原理:空气通过过滤器和加热装置后,进入干燥室顶部的热风分配器,通过热风分配器的热空气均匀地进入干燥室,并成螺旋状流动,同时将料液送到安装在干燥室顶部的离心喷雾头,料液被雾化成很小的雾状液滴,使料液和热空气接触的表面积大大增加,水分很快蒸发,在很短的时间内形成干燥成品。

Its working principle: horizontal spray drier air through the filter and heating devices, into the drying chamber at the top of the hot air distributor, through the hot air distributor of hot air to evenly into the drying chamber, and a spiral flow, at the same time to send material liquid to install in the drying chamber at the top of the centrifugal spray head, the material liquid is atomized into small fog droplets, make the material liquid significantly increased surface area of contact with the hot air, moisture to evaporate quickly, form dry products in a very short period of time.

随着喷雾干燥的不断开发和完善,卧式喷雾干燥物料热敏性、粘度、流动性等不同的干燥特性,和产品的颗粒大小、粒度分布、残留水份含量、堆积密度、颗粒形状等不同的质量要求,例如用于食品工业中奶粉、乳清粉、奶油粉、蛋粉、果汁粉、速溶咖啡等的生产中,在其它工业如生物制品、洗涤剂、陶瓷等工业中也很常用。

With the continuous development of spray drying and improvement of horizontal spray drying was dry heat-sensitive materials, different drying properties such as viscosity, liquidity, and the product particle size, particle size distribution, residual moisture content, bulk density, particle shape, such as different quality requirements, such as used in the food industry of milk powder, whey powder, cream powder, egg powder, fruit juice powder, instant coffee production, such as in other industries such as biological products, detergent, ceramic industry is also very common.

二、WZ系列卧式喷雾干燥机--设备特点

WZ series horizontal spray dryer - equipment features

卧式喷雾干燥机的粉料集中出料,即只有一个出粉口,从而解决了管道内的集料问题及产品粉末的颗粒度及含水量的一致性,保证了产品质量,提高了产品品相。减少粉料干燥后管道内的停留时,有效保护产品的活性成分。

Horizontal spray dryer powder concentrated discharge, that is, only a powder mouth, so as to solve the problem of aggregates in the pipeline and the consistency of powder granularity and water content, to ensure the quality of products, improve the product phase. Effectively protect the active ingredient of the product when reducing the stay in the pipeline after powder drying.

卧式喷雾干燥机对物料的雾化、热风脱水干燥、低速循环刮板粉末输送、排风布袋除尘、出粉等一系列工艺过程都在同一个紧凑的干燥箱体内连续完成;占地面积小,内部易清洗,热能损失小,特有的尾气热能回收系统可以显著的降低能源消耗,提高干燥机的热量综合利用率。

Horizontal spray dryer for material atomization, hot air dehydration and drying, low-speed circulation scraper powder transmission, exhaust bag dust removal, powder production and a series of technological processes are in the same compact dryer body continuous completion; It covers a small area, is easy to clean, and has a small loss of heat energy. The unique tail gas heat recovery system can significantly reduce energy consumption and improve the comprehensive utilization of heat of the dryer.

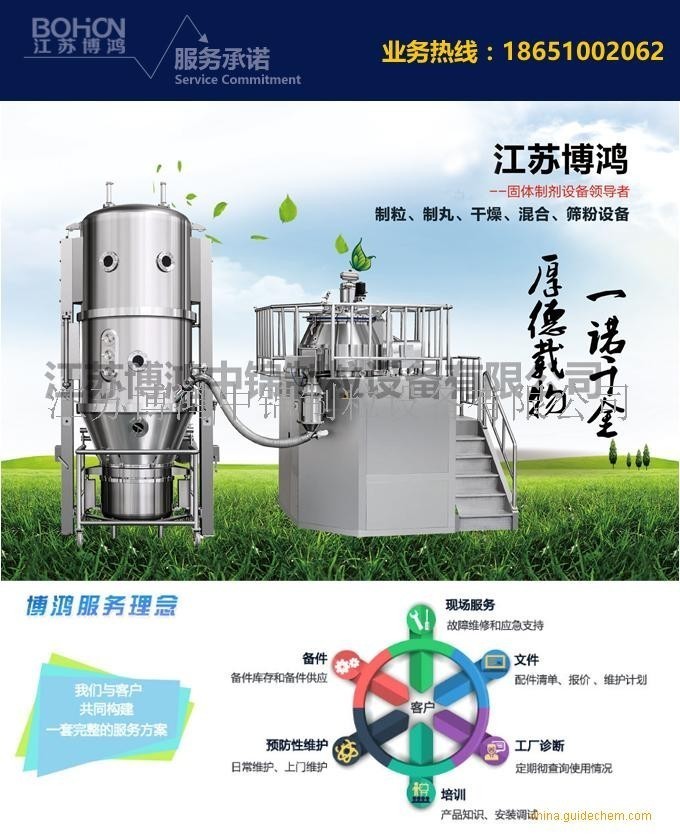

FPCG系列流化床喷雾干燥制粒机

FPCG series fluidized bed spray drying granulator

流化床沸腾干燥制粒机|流化床喷雾干燥制粒机|流化床沸腾制粒机

Fluidized bed boiling drying granulator |Fluidized bed spray drying granulator |Fluidized bed boiling granulator

江苏博鸿提供的流化床沸腾干燥制粒机,流化床喷雾干燥制粒机,流化床沸腾制粒机,卧式沸腾干燥机,振动流化床干燥机,高效沸腾干燥机,流化床底喷包衣机,高效包衣机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥制粒包衣设备性能稳定,模块化设计,为您提供先进的喷雾干燥制粒包衣整体解决方案和实验制粒干燥工艺实验样机。江苏博鸿是高品质喷雾干燥制粒包衣设备生产厂家,已提供超数百套高品质喷雾干燥制粒包衣设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong fluidized bed boiling drying granulator, fluidized bed spray drying granulator, fluidized bed boiling granulator, horizontal boiling dryer, vibrating fluidized bed dryer, high efficiency boiling dryer, fluidized bed bottom spray coating machine, high efficiency coating machine, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying granulator coating equipment stable performance, modular design, to provide you with advanced spray drying granulator coating overall solution and experimental granulator drying process experimental prototype. Jiangsu bohong is a manufacturer of high quality spray drying granulation coating equipment, has provided more than hundreds of sets of high quality spray drying granulation coating equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

一、FPCG系列流化床喷雾干燥制粒机--设备概述

FPCG series fluidized bed spray drying granulator - equipment overview

流化床喷雾干燥制粒机集喷雾干燥/流化制粒于一体,实现液态物料一步法制粒;特别适用微辅料,热敏性物料,采用喷雾工艺,更适用于多糖成分,粘稠性强或热敏性的产品。喷雾干燥室、捕集室、流化床及二次供风系统等结构进行了重要的修改后,更加贴切的表现出喷雾干燥的特性。适用于中成药制备冲剂、胶囊、片剂颗粒或对颗粒进行包衣。

Fluidized bed spray drying granulator integrates spray drying/fluidized granulator to realize one-step granulation of liquid materials; Especially suitable for micro excipients, heat sensitive materials, using spray process, more suitable for polysaccharides, viscous or heat sensitive products. The structure of spray drying chamber, capture chamber, fluidized bed and secondary air supply system has been significantly modified to show the characteristics of spray drying. It is suitable for preparing granule, capsule, tablet or coating granule of Chinese patent medicine.

三、FPCG系列流化床喷雾干燥制粒机--设备优势

FPCG series fluidized bed spray drying granulating machine -- equipment advantages

流化床喷雾干燥制粒机生产的颗粒速溶、冲剂易于溶出、片剂易于崩解;设备于密封负压下工作,内表面光洁,无死角,利于清洗,符合GMP要求。

The granules produced by fluidized bed spray drying granulator are easy to dissolve, the granule is easy to dissolve and the tablet is easy to disintegrate. The equipment works under sealed negative pressure, the inner surface is smooth and clean, without dead Angle, which is conducive to cleaning and in line with GMP requirements.

实验型,中试型,生产型流化床的气流结构都是按照同一个技术标准设计的,所以产品的平行放大性和重现性会很好。

Experimental, pilot and production fluidized beds are all designed according to the same technical standard, so the products will have good parallel amplification and reproducibility.

罗列3个设备优势,仅供参考。

2.1、气流结构

?1、筒体的结构经过 的空气动力学的计算

?2、均匀的气流带动物料在筒体里均匀的循环运动

?3、通过气流的风速控制来控制物料的上升和沉降速度

?4、结合喷枪的性能使制粒和包衣达到*的效果

?5、根据物料的性质、粒径的大小、辅料的性质可进行针对性的气流设计

?6、能获得粒径分布均匀的颗粒,能高效均匀的进行上药和包衣

?7、跟普通流化床比,能制得粒径范围更窄的颗粒,包衣的效率要高出普通流化床一倍以上。

List 3 equipment advantages for reference only.

2.1 Air flow structure

· 1. The cylinder structure is calculated by accurate aerodynamics

· 2. Uniform air flow drives the material to circulate evenly in the cylinder

· 3. The rising and settling speeds of materials are controlled by the wind speed control of airflow

· 4. Combined with the performance of the spray gun, pelletizing and coating can achieve the best effect

· 5. Specific airflow design can be carried out according to the properties of materials, particle size and auxiliary materials

· 6. Particles with uniform particle size distribution can be obtained, which can be applied and coated efficiently and evenly

· 7. Compared with ordinary fluidized bed, it can produce particles with a narrower particle size range, and the coating efficiency is more than twice that of ordinary fluidized bed.

2.2、过滤袋

?1、进口5/10/20/30/50微米的防静电过滤袋

?2、物料不易粘附堵

?3、提高产品收率

?4、保持良好的通风率

?5、易清洁,不易交叉污染

2.2、Filter bag

· 1. Import 5/10/20/30/50 micron anti-static filter bag

· 2. Materials are not easy to stick and block

· 3. Increased product yield

· 4. Maintain good ventilation rate

· 5. Easy to clean and not easy to cross contamination

2.3、高速喷枪

?1、外混式喷枪

?2、雾化液滴的粒径可调节

?3、雾化的角度可调节

?4、雾化颗粒的粒径很均匀,没有脉冲现象

?5、大流量缩短制粒和包衣的时间

?6、跟普通喷枪比,节省原料和辅料的使用量

2.3 High speed spray gun

· 1. Mixed spray gun

· 2. Particle size of atomized droplets can be adjusted

· 3. Atomization Angle can be adjusted

· 4. Atomized particle size is very uniform without pulse

· 5. Reduce pelletizing and coating time with large flow rate

· 6. Compared with ordinary spray guns, it can save the use of raw materials and accessories

Scope of applicable products of spray dryer

《Drying engineering of amino acid and organic acid products》

1. Amino acid products: glutamic acid, lysine, methionine, tryptophan, threonine, phenylalanine, glycine, alanine, cystine, cysteine, serine, tyrosine, proline, arginine, histidine, ornithine, citrulline, theanine, branched amino acid, etc.

2. Organic acid products: citric acid, gluconic acid, lactic acid, itaconic acid, tartaric acid, malic acid, succinic acid, pyruvate, long-chain dibasic acid, fatty acid, etc.

《Drying engineering of starch and starch sugar products》

1, contract starch sugar and corn starch, potato starch, corn protein powder, corn oil, protein feed, various DE value glucose syrup, maltose, maltodextrin, fructose syrup, various USES of modified starch, high water absorption starch, binder, etc.

2. Polyol products: sorbitol, xylitol, maltitol, sugarcane.

3. Dew alcohol, lactose alcohol, iso-maltoketol, arabinol, erythritum.

4. Alcohol, propylene glycol, 1-3 propylene glycol, glycol, butanediol, hydrogenated 5) starch syrup, sugar alcohol and its derivatives.

《Drying engineering of enzyme preparation products》

Amylase, glycosylase, protease, cellulase, isoamylase, isomerase, glucanase, pectinase, lipase, xylanase, etc.

《Yeast and its derivatives products》

Contract high activity dry yeast, medicinal yeast, feed yeast, nutritional yeast, yeast extract, etc.

《Drying engineering of functional fermentation products》

Lentinan, ganoderma lucidum polysaccharide, cordyceps sinensis, red koji pigment, oligomeric isomaltose and various functional sugar alcohol, etc.

《Slaughterhouse by-products》

Blood and fish products: animal protein, blood (dark albumin, light albumin), fish protein, fish meal, brain, fish sauce, glue and hydrolyzed glue, liver and whale sauce.

《Dairy drying project》

Contracted UHT milk, pasteurized milk, yogurt, color milk, lactic acid drinks, all kinds of milk powder, ice cream, condensed milk, cheese, cream, casein, milk beer and other projects.

《Instant granulation and drying project of various powder materials》

Contracted all kinds of nutritional powder, coffee companion, bone powder, blood powder, meat powder, sodium casehydrochloride and other projects.

《Drying engineering of fruit and vegetable products》

Contracted pumpkin powder, apple juice, lotus seed milk, lotus seed tea, lotus paste biscuits, citrus wine, hawthorn powder, carrot powder, licorice powder, peanut powder, peanut oil and other projects.

《Soybean drying project》

Contract soy flour, soy milk, soy yogurt, soy protein separation and other projects.