-

你好,欢迎来到江苏博鸿中锦制粒设备有限公司官网!

|

| 外型尺寸 | 2*5*8 |

| 品牌 | FPCG系列流化床高效沸腾干燥机Fluidized bed high efficiency boiling dryer |

| 货号 | FPCG-150 |

| 用途 | 江苏博鸿提供的卧式沸腾干燥机,振动流化床干燥机,卧式流化床沸腾干燥机,双锥真空干燥机,流化床沸腾干燥机,高效沸腾干燥机,流化床干燥机,喷雾干燥制粒机,符合医药GMP/FDA要求。 |

| 型号 | FPCG-150 |

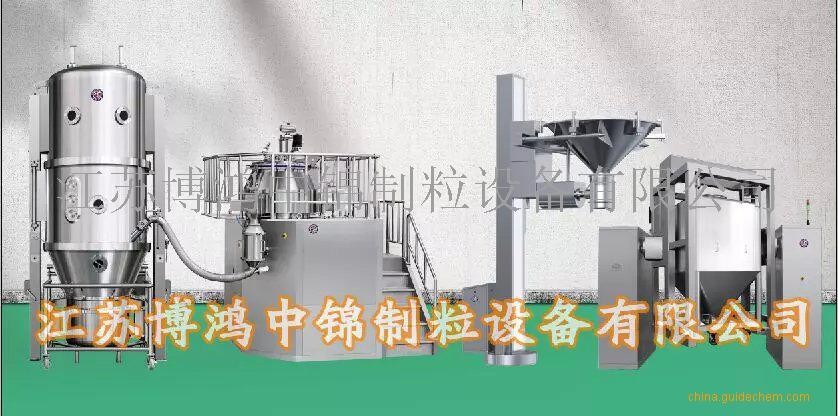

FPCG系列流化床高效沸腾干燥机

FPCG series fluidized bed high efficiency boiling dryer

江苏博鸿提供的卧式沸腾干燥机,振动流化床干燥机,卧式流化床沸腾干燥机,双锥真空干燥机,流化床沸腾干燥机,高效沸腾干燥机,流化床干燥机,喷雾干燥制粒机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥设备性能稳定,模块化设计,为您提供先进的喷雾干燥整体解决方案和实验喷雾干燥工艺实验样机。江苏博鸿是高品质喷雾干燥设备生产厂家,已提供超数百套高品质喷雾干燥设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong offers horizontal boiling dryer, vibrating fluidized bed dryer, horizontal fluidized bed boiling dryer, double-cone vacuum dryer, fluidized bed boiling dryer, efficient boiling dryer, fluidized bed dryer, spray drying granulator, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying equipment stable performance, modular design, to provide you with advanced spray drying solutions and experimental spray drying process experimental prototype. Jiangsu bohong is a high quality spray drying equipment manufacturers, has provided more than hundreds of high quality spray drying equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

一、FPCG系列流化床高效沸腾干燥机--设备概述

江苏博鸿所有的生产型流化床均可实现水平和垂直方向的物料流程设计。上料可以通过物料自身的重力或者通过抽吸的方式来完成。

流化床物料槽可移动并翻转出料(达到一定的批量生产时)。 通过升降柱提升可以实现无尘上料和卸料。

流化床出料也可以通过侧面的抽吸,或者通过垂直方向利用物料自身的重力和旋转的物料槽底部结构来实现,底部翻转出料是流化床出料方法中*的。

FPCG series fluidized bed high efficiency boiling dryer -- equipment overview

All production-type fluidized beds in jiangsu bohong can be designed for horizontal and vertical material flow. Feeding can be done by the material's own gravity or by pumping.

Fluidized bed material tank can be moved and turned out (when certain batch production is achieved). Dust-free feeding and unloading can be realized by lifting column.

Fluidized bed discharge can also be achieved by side suction, or by using the gravity of the material itself in the vertical direction and the structure of the bottom of the rotating material trough. Bottom flip discharge is the most effective discharge method in fluidized bed.

二、FPCG系列流化床高效沸腾干燥机--产品功能

※ A、干燥功能:湿物料进行负压干燥

※ B、制粒功能:制成的颗粒更均匀、细粉少、流动性更好

※ C、包衣功能:可以对颗粒、微丸、药物粉末进行功能层包衣;也可对颗粒、微丸进行药物敷层包衣。

FPCG series fluidized bed high efficiency boiling dryer - product function

※ A. Drying function: negative pressure drying for wet materials

※ B. Granulation function: the granule is more uniform, with less fine powder and better fluidity

※ C. Coating function: it can coat particles, pellets and pharmaceutical powder with functional layer; Drug coating can also be applied to particles and pellets.

三、FPCG系列流化床高效沸腾干燥机--产品特点

※ 设备结构紧凑,体积较小,占地面积少,可方便移动。

※ 密闭式的操作系统,避免交叉污染。

※ 风量由变频风机控制,具有能耗低、噪音低等优点。

※ 温度控制精确,波动范围小。

※ 3个过滤室轮流清粉,在保证流化状态情况下,保证了滤袋的通透性。

※ 引进德国先进的打磨抛光技术,设备表面更加精美。

※ 设备结构简单,拆装方便,无死角,易于清洗干净。

※ 精心设计的气流分布结构,气流分布更均匀,效率更高,产品质量更稳定且重现性好。

※ 设备电器控制简单,性能稳定可靠,元器件易维修更换。

※ 实验型,中试型,生产型流化床的气流结构都是按照同一个技术标准设计的,所以将来产品的平行放大性和重现性会很好。

FPCG series fluidized bed high efficiency boiling dryer - product features

※The device is compact in structure, small in size, occupies less space, and is easy to move.

※ closed operating system to avoid cross contamination.

※ the air volume is controlled by a variable frequency fan, which has the advantages of low energy consumption and low noise.

※ accurate temperature control with small fluctuation range.

※ 3 filter rooms take turns to clean the powder, ensuring the permeability of the filter bag under the condition of fluidization.

※ the introduction of advanced polishing technology from Germany makes the surface of the equipment more exquisite.

※ the equipment has simple structure, easy to disassemble and assemble, no dead corner and easy to clean.

※Carefully designed airflow distribution structure makes airflow distribution more uniform, higher efficiency, more stable product quality and better reproducibility.

※Equipment electrical control is simple, the performance is stable and reliable, components easy to repair and replace.

※Experimental, pilot and production fluidized beds are all designed according to the same technical standard, so the products will have good parallel amplification and reproducibility in the future.

四、FPCG系列流化床高效沸腾干燥机--独特的技术

江苏博鸿生产的流化床针对不同的工艺装置可以灵活互换。顶喷物料槽。可用于制粒、干燥和粉末包衣。 大面积的底部设计,达到了*的风量流通,从而大大提高了干燥效率。标准的底部筛网设计,容易清洁。符合大部分产品和工艺的需求。

※ 所有生产型流化床均设计了*的风量分布结构。

※ 锥形泄压区使产品的流速减慢,从而能够得到更好的产品。

※ 不同的底部设计保证产品的*流入。

※ 双室过滤系统,确保了持续的流化状态,即使在振荡清灰时。

※ 我们可以针对不同产品的需要提供不同的过滤袋。 过滤袋更换方便。

FPCG series fluidized bed high efficiency boiling dryer -- unique technology

The fluidized bed produced by jiangsu bohong can be exchanged flexibly for different process devices. Top jet material tank. Can be used for granulating, drying and powder coating. Large area of the bottom design, to achieve the best air flow, thus greatly improve the drying efficiency. Standard bottom screen design, easy to clean. Meets the requirements of most products and processes.

※ Optimal air flow distribution structures are designed for all production fluidized beds.

※ The tapered relief zone slows down the flow of the product so that a better product can be obtained.

※ Different bottom designs ensure optimal flow of products.

※ Dual chamber filtration system ensures continuous fluidization even during oscillating ash removal.

※ We can provide different filter bags for different products. The filter bag is easy to replace.

《喷雾干燥机适用产品范围》

Scope of applicable products of spray dryer

《氨基酸及有机酸类产品干燥工程》

《Drying engineering of amino acid and organic acid products》

1、承揽氨基酸类产品:谷氨酸、赖氨酸、蛋氨酸、色氨酸、苏氨酸、苯丙氨酸、甘氨酸、丙氨酸、胱氨酸、半胱氨酸、丝氨酸、酪氨酸、脯氨酸、精氨酸、组氨酸、鸟氨酸、瓜氨酸、茶氨酸、支链氨基酸等。

1. Amino acid products: glutamic acid, lysine, methionine, tryptophan, threonine, phenylalanine, glycine, alanine, cystine, cysteine, serine, tyrosine, proline, arginine, histidine, ornithine, citrulline, theanine, branched amino acid, etc.

2、承揽有机酸类产品:柠檬酸、葡萄糖酸、乳酸、衣康酸、酒石酸、苹果酸、琥珀酸、丙酮酸、长链二元酸、脂肪酸等。

2. Organic acid products: citric acid, gluconic acid, lactic acid, itaconic acid, tartaric acid, malic acid, succinic acid, pyruvate, long-chain dibasic acid, fatty acid, etc.

《淀粉及淀粉糖类产品干燥工程》

1、承揽淀粉糖及玉米淀粉、薯类淀粉、玉米蛋白粉、玉米油、蛋白饲料、各种DE值葡萄糖浆、麦芽糖、麦芽糊精、果葡糖浆、各种用途的变性淀粉、高吸水淀粉、粘结剂等。

《Drying engineering of starch and starch sugar products》

1, contract starch sugar and corn starch, potato starch, corn protein powder, corn oil, protein feed, various DE value glucose syrup, maltose, maltodextrin, fructose syrup, various USES of modified starch, high water absorption starch, binder, etc.

2、多元醇类产品:山梨醇、木糖醇、麦芽糖醇、甘蔗。

2. Polyol products: sorbitol, xylitol, maltitol, sugarcane.

3、露醇、乳糖醇、异麦芽酮糖醇、阿拉伯糖醇、赤藓。

3. Dew alcohol, lactose alcohol, iso-maltoketol, arabinol, erythritum.

4、醇、丙二醇、1-3丙二醇、乙二醇、丁二醇、氢化5)淀粉糖浆、糖醇及其衍生物。

4. Alcohol, propylene glycol, 1-3 propylene glycol, glycol, butanediol, hydrogenated 5) starch syrup, sugar alcohol and its derivatives.

《酶制剂类产品干燥工程》

承揽淀粉酶、糖化酶、蛋白酶、纤维素酶、异淀粉酶、异构酶、β—萄聚糖酶、植酸酶、果胶酶、脂肪酶、木聚糖酶等。

《Drying engineering of enzyme preparation products》

Amylase, glycosylase, protease, cellulase, isoamylase, isomerase, glucanase, pectinase, lipase, xylanase, etc.

《酵母及其衍生物类产品》

承揽高活性干酵母、药用酵母、饲料酵母、营养酵母、酵母抽提物等。

《Yeast and its derivatives products》

Contract high activity dry yeast, medicinal yeast, feed yeast, nutritional yeast, yeast extract, etc.

《功能发酵制品类产品干燥工程》

承揽香菇多糖、灵芝多糖、冬虫夏草、红曲色素、低聚异麦芽糖及各种功能糖醇等。

《Drying engineering of functional fermentation products》

Lentinan, ganoderma lucidum polysaccharide, cordyceps sinensis, red koji pigment, oligomeric isomaltose and various functional sugar alcohol, etc.

《屠宰场副产品》

承揽血和鱼制品类:动物蛋白、血(深色白蛋白、浅色白蛋白)、鱼蛋白、鱼粉、脑、鱼露、胶与水解胶、肝和鲸露。

《Slaughterhouse by-products》

Blood and fish products: animal protein, blood (dark albumin, light albumin), fish protein, fish meal, brain, fish sauce, glue and hydrolyzed glue, liver and whale sauce.

《乳制品干燥工程》

承揽UHT奶、巴氏奶、酸奶、花色奶、乳酸饮料、各种奶粉、冰淇淋、炼乳、干酪、奶油、干酪素、奶啤等工程。

《Dairy drying project》

Contracted UHT milk, pasteurized milk, yogurt, color milk, lactic acid drinks, all kinds of milk powder, ice cream, condensed milk, cheese, cream, casein, milk beer and other projects.

《各种粉料速溶造粒干燥工程》

承揽各种营养粉剂、咖啡伴侣、骨粉、血粉、肉粉、酪盐酸钠等工程。

《Instant granulation and drying project of various powder materials》

Contracted all kinds of nutritional powder, coffee companion, bone powder, blood powder, meat powder, sodium casehydrochloride and other projects.

《果蔬制品干燥工程》

承揽南瓜粉、苹果汁、莲子乳、莲芯茶、莲蓉饼干、柑桔酒、山楂粉、胡萝卜粉、甘草粉、花生粉、花生油等工程。

《Drying engineering of fruit and vegetable products》

Contracted pumpkin powder, apple juice, lotus seed milk, lotus seed tea, lotus paste biscuits, citrus wine, hawthorn powder, carrot powder, licorice powder, peanut powder, peanut oil and other projects.

《豆制品干燥工程》

承揽豆粉、豆奶、豆酸奶、大豆分离蛋白等工程。

《Soybean drying project》

Contract soy flour, soy milk, soy yogurt, soy protein separation and other projects.