-

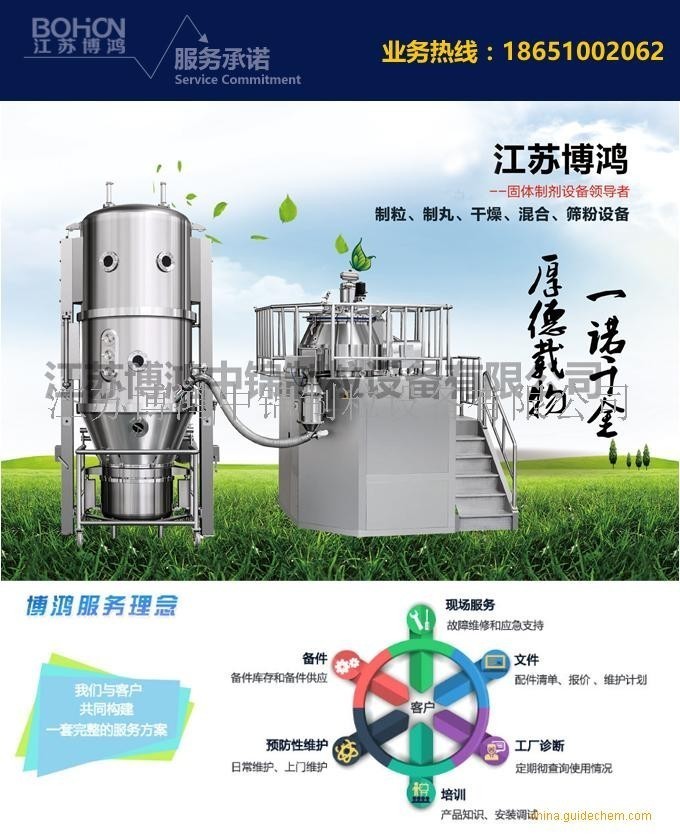

你好,欢迎来到江苏博鸿中锦制粒设备有限公司官网!

|

| 外型尺寸 | 3*5*8 |

| 品牌 | 磷酸铁锂-正负极新材料专用高速离心喷雾干燥机,烘干机设备 |

| 货号 | MSD-100 |

| 用途 | 磷酸铁锂-正负极新材料专用高速离心喷雾干燥机,烘干机设备 |

| 型号 | MSD-100 |

| 制造商 | 磷酸铁锂-正负极新材料专用高速离心喷雾干燥机,烘干机设备 |

| 是否进口 |

MSD series high speed centrifugal spray dryer

喷雾干燥机|上排风流化床喷雾干燥制粒机|卧式压力喷雾造粒干燥机

Spray dryer | Upper exhaust fluidized bed spray drying granulator |

Horizontal pressure spray granulator dryer

江苏博鸿提供的喷雾干燥机,压力喷雾干燥塔,离心式喷雾干燥机,卧式压力喷雾干燥机,流化床喷雾干燥制粒机,上排风多级流化床喷雾造粒干燥机,中药浸膏喷雾干燥机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥设备性能稳定,模块化设计,为您提供先进的喷雾干燥整体解决方案和实验喷雾干燥工艺实验样机。江苏博鸿是高品质喷雾干燥设备生产厂家,已提供超数百套高品质喷雾干燥设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong spray dryer, pressure spray drying tower, centrifugal spray dryer, horizontal pressure spray dryer, fluidized bed spray granulating machine, upper exhaust multi-stage fluidized bed spray granulating dryer, Chinese medicine extract spray dryer, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying equipment stable performance, modular design, to provide you with advanced spray drying solutions and experimental spray drying process experimental prototype. Jiangsu bohong is a high quality spray drying equipment manufacturers, has provided more than hundreds of high quality spray drying equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

一、MSD系列高速离心喷雾干燥机--设备概述

MSD series high-speed centrifugal spray dryer -- equipment overview

高速离心喷雾干燥机主要适用于高校、研究所和食品医药化工企业实验室生产微量颗粒粉末,对所有溶液如乳浊液、悬浮液具有广谱适用性,适用于对热敏感性物的干燥如生物制品、生物农药、酶制剂等,因所喷出的物料只是在喷成雾状大小颗粒时才受到高温,故只是瞬间受热,能保持这些活性材料在干燥后仍维持其活性成份不受破坏。

High-speed centrifugal spray drying machine is mainly suitable for colleges and universities, research institutes and the food and medicine and chemical industry enterprise laboratory trace particles of powder production, such as emulsion, suspending liquid has a broad spectrum of all solution applicability, suitable for drying thermal sensitivity material such as biological products, biological pesticide, enzymes, because of overflowing material only when sprayed into mist particle size under high temperature, it is just instant heating, can maintain the active material in dry hind still maintain its active ingredients are not destroyed.

二、MSD系列高速离心喷雾干燥机--工作原理

MSD series high speed centrifugal spray dryer - working principle

空气经过滤和加热,进入干燥器顶部空气分配器,热空气呈螺旋状均匀地进入干燥室。料液经塔体顶部的高速离心雾化器,旋转喷雾成极细微的雾状液珠,与热空气并流接触在极短的时间内可干燥为成品。

The air is filtered and heated and enters the air distributor at the top of the dryer. The feed liquid passes through the high speed centrifugal atomizer on the top of the tower body, and turns the spray into extremely fine mist droplets, which can be dried into finished products in a very short time after contacting with the hot air.

喷雾干燥机热气流与雾滴的接触:有足够量的热气流进入喷雾干燥室时,必须考虑热气流的方向及角度,无论是并流、逆流还是混流,确保与雾滴的充分接触,才能进行充分的热交换。

Contact between hot air flow and fog droplets in spray dryer: when enough hot air flow enters the spray drying chamber, the direction and Angle of hot air flow must be considered, whether it is parallel flow, reverse flow or mixed flow, to ensure the full contact with fog droplets, in order to carry out full heat exchange.

喷雾干燥机成品连续地由干燥塔底部和旋风分离器中输出,废气由风机排空。整套喷雾系统易清洁、无死角,符合GMP要求。

The finished product of the spray dryer is continuously output from the bottom of the drying tower and the cyclone separator. The whole spray system is easy to clean, no dead corner, in line with GMP requirements.

三、MSD系列高速离心喷雾干燥机--产品特点

MSD series high speed centrifugal spray dryer -- product features

《1》高速离心喷雾干燥机干燥速度快,料液经雾化后表面积大大增加,在热风气流中,瞬间就可蒸发95%-98%的水份,完成干燥时间仅需数秒钟,特别适用于热敏性物料的干燥。

High speed centrifugal spray dryer drying speed, the surface area of the material after atomization greatly increased, in the hot air flow, can instantly evaporate 95-98% of the water, drying time only a few seconds, especially suitable for the drying of heat-sensitive materials.

《2》高速离心喷雾干燥机产品具有良好的均匀度、流动性和溶解性,产品纯度高,质量好。对于含湿量40—60%(特殊物料可达90%)的液体能一次干燥成粉粒产品,干燥后不需粉碎和筛选,减少生产工序,提高产品纯度。对产品粒径、松密度、水份,在一定范围内可通过改变操作条件进行调整,控制和管理都很方便。

High speed centrifugal spray dryer has good uniformity, fluidity and solubility, high purity and good quality. For the liquid with moisture content of 40-60% (up to 90% for special materials), it can be dried into powder products at one time. After drying, there is no need to crush and screen, which can reduce the production process and improve the product purity. The product size, loose density and moisture can be adjusted by changing the operating conditions within a certain range, which is very convenient for control and management.

《3》喷雾干燥机采用彩色大触摸屏操作,全自动控制和手动控制相结合,满足用户调节各项参数的要求,在干燥温度控制的设计上采用实时调控PID恒温控制技术。

The spray dryer is operated with a large color touch screen, with the combination of automatic control and manual control to meet the user's requirements for adjusting various parameters. In the design of drying temperature control, the machine adopts real-time PID thermostatic control technology.

《4》生产过程简化,操作控制方便。一键式开机,全自动控制。设定喷雾工艺参数后,温度到达预定温度,泵自行启动,触摸屏上显示运行动画,运行流程清晰显示;关机时只需按停止键,机器自动安全关机。

The production process is simplified and the operation and control are convenient. One-button startup, fully automatic control. After setting the spray process parameters, the temperature reaches the predetermined temperature, the pump starts up by itself, the running animation is displayed on the touch screen, and the running process is clearly displayed. When the machine is shut down, just press the stop button and the machine will shut down automatically and safely.